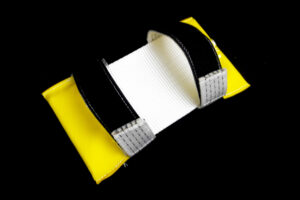

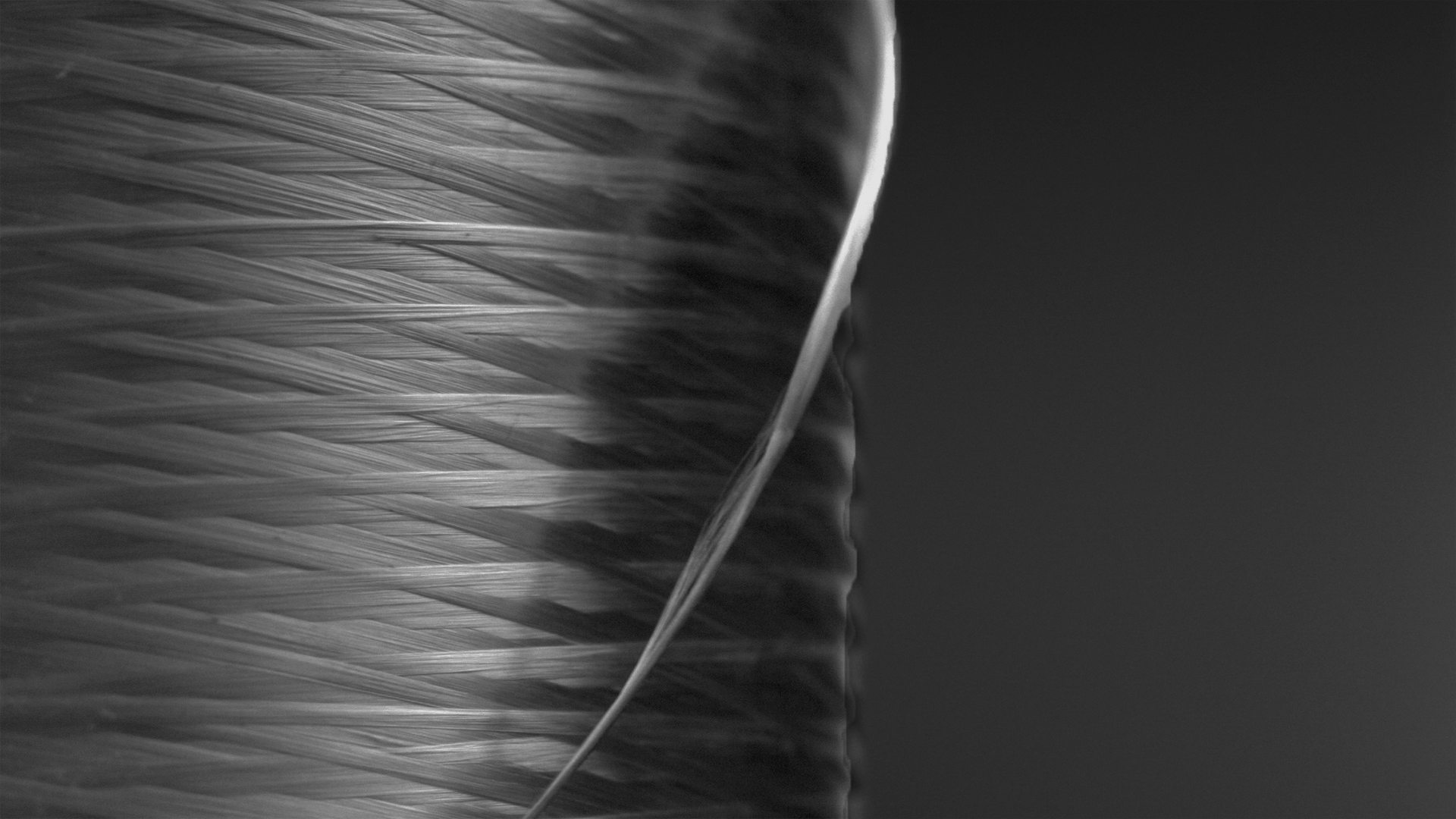

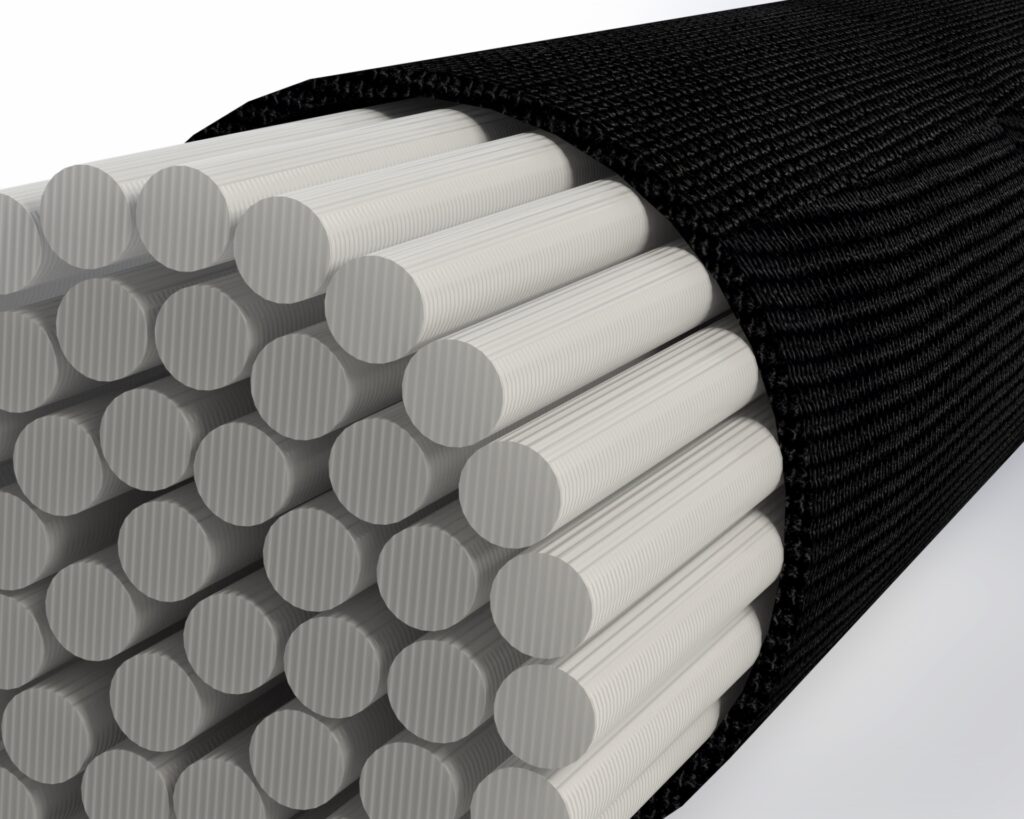

Extreema® round slings are constructed using advanced parallel-laid fiber technology, forming the sling’s core. The core of every Extreema® round sling is made exclusively of 100% high-performance fibers, including Dyneema®, known as the world’s strongest fiber™, and Trosar® (general HMPE). These superior fibers ensure exceptional strength and durability, making Extreema® round slings an ideal choice for heavy-duty lifting and rigging applications.

Bio-Based Dyneema® Core

Bio-Based Dyneema® is an Ultra High Molecular Weight PolyEthylene (UHMWPE) fiber renowned for its unmatched strength-to-weight ratio. Developed by DSM in the Netherlands, this bio-based wonder fiber is often called “the world’s strongest fibre”™. Dyneema® yarn is manufactured in the EU and US, ensuring availability and quality for customers worldwide.

The secret behind Dyneema®’s superior performance lies in its incredibly long molecular chains, which distribute loads more efficiently across the polymer backbone. This results in a fiber that offers maximum strength and minimal weight, making it a top choice for high-performance applications where strength and weight are critical factors. Trust Dyneema® to deliver exceptional performance in the most challenging conditions.

- Lightweight and flexible, easy to handle

- Less than 1% stretch at W.L.L., suitable for calculated lifts

- D:d = 1:1 for round slings up to 200T; above this D:d = 1:1,5

- Resistant against chemicals

- Does not absorb water

- Floats on water

- Long life cycle

- Bio-based

Aramid Core

Aramid is a synthetic fibre known for its remarkable strength and heat resistance. Aramid fibres are commonly used in high-performance applications that require exceptional durability. The aramid core is known for its high strength-to-weight ratio, excellent cut resistance, and abrasion resistance. The combination of aramid and other high-performance fibres creates a round sling that is strong, lightweight, and versatile. Trust aramid core for reliable performance in the most challenging applications.

HMPE Core

High-modulus PolyEthylene (HMPE) is a strong and durable material due to its long chains, which efficiently transfer loads and enhance interactions between molecules. This results in a rigid material with the highest impact strength of any thermoplastic.

HMPE is highly resistant to corrosive chemicals (excluding oxidizing acids), has low moisture absorption and friction, and is self-lubricating and abrasion-resistant. Although there’s limited long-term research, HMPE is manufactured to consistent quality standards by DSM in the Netherlands in Asia, making it reliable and high-performing in various applications.

Core

Features Comparison

| Dyneema | HMPE | Aramid | Polyester | |

|---|---|---|---|---|

| Price | €€€ | €€ | €€ | € |

| Strength to weight ratio (cN/dtex)* | 35,1 | 32,5 | 21,8 | 8,2 |

| Chemical resistance | Excellent (1) | Excellent (2) | Poor | Poor |

| Temp. range (°C) | -180 - +70 (3) | -180 - +70 (3) | -180 – +200 (4) | -40 – +100 |

| Capacity range (MBL (metric ton)) (5) | 3,5 – 4500 | 3,5 – 4500 | 14 – 700 | 3,5 - 1400 |

| Length range (m) (6) | 0,5 - 65 | 0,5 - 65 | 0,5 - 65 | 0,5 - 65 |

| Specific gravity | 0,975 | 0,975 | 1,45 | 1,38 |

| Moisture resistance | Excellent (7) | Excellent (7) | Poor | Poor |

| Elongation at use (%) (8) | 0,5 – 1 | 0,5 – 1 | 0,6 – 1 | 3-5 |

| Elongation at break (%) | 3-4 | 3-4 | 4 | 10-14 |

1) Including extensive datasheets. Specific chemicals can be tested on request at yarn supplier.

2) Excluding extensive datasheets.

3) Strength decreases at higher temperatures. Max. temp for long exposure is 70 °C. More detailed info on request.

4) Remains full strength at max. temperature of 200 °C.

5) Capacity in straight pull configuration.

6) Length depending on WLL. Range is approximate. Higher/lower on specific request.

7) Does not absorb water.

8) Based on safety factor 7.